TRACK AND TRACK FRAMES

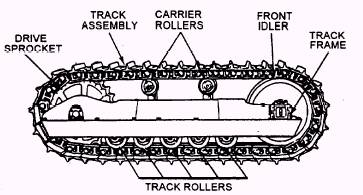

Learning Objective: Identify the operational components of the track and track frame. Describe the maintenance procedures used on tracks and track frame assemblies. The undercarriage of crawler-mounted equipment contains two major components- TRACK ASSEMBLY and TRACK FRAME. This under-carriage (fig. 6-18) is provided on equipment that must have positive traction to operate efficiently.

TRACK ASSEMBLY

The track assembly consists of a continuous chain surrounding the track frame and drive sprocket. The links of the chain provide a flat surface for the track rollers to pass over, as they support the equipment. Track shoes are bolted to the outside links of the chain and distribute the weight of the equipment over a large surface area.

Track Chain

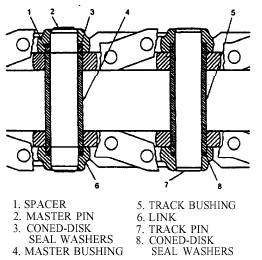

Figure 6-19 shows a cutaway view of a section of track chain, showing the internal arrangement of the pins and bushings. As the tractor operates, the drive sprocket teeth contact the track pin bushings and propel the tractor along the track assembly.

Figure 6-19.- Track chain cutaway.

The pins and bushings wear much faster than other parts of the track because of their constant pivoting, as the track rotates around the track frame. This pivoting results in internal wear of both the pin and the bushing. As the pins and bushings wear, the track lengthens. When it does, the track is adjusted to remove excessive slack.

Bushings that show lots of wear on the outside are good indicators of inner wear that is also nearing the maximum allowed by the manufacturer, if the track is to be rebuilt. To determine whether the track should be removed for rebuilding or replacement, measure the outside of the bushings and track "pitch" (length of the track). Use an outside caliper and ruler, as shown in figure 6-20. Measure the outside of the bushing where it shows the most wear and compare it to the manufacturer's specifications.

Figure 6-18.- Side view of crawler tractor chassis.

Measure track pitch with a ruler or tape measure after tightening the track to remove any slack, as shown in figure 6-21.

Should the bushing wear or track length be excessive, remove the track for rebuilding unless facilities and time do not permit. Rebuilding a track will nearly double the useful life of the pin and bushings.

Figure 6-20.- Bushing wear measurement.

Figure 6-21.- Track pitch measurement.