Custom Search

|

|

|

|

|

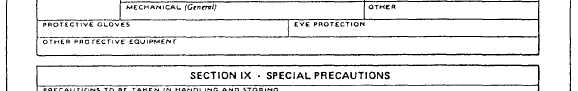

WORK CENTER RESPONSIBILITIES All work center supervisors have specific responsibilities under the TCP. All tool containers should have a lock and key as part of their inventory. The supervisor should be aware of the location of each containers keys and have a way of controlling them. When work is to be completed away from the work spaces (for example, the flight line/flight deck), complete tool containers, not a handful of tools, should be taken to the job. If more tools are needed than the tool container contains, tool tags can be used to check out tools from other tool containers in the work center or from another work center. The following is a list of additional responsibilities of the work center supervisor:1. Upon task assignment, note the number of the tool container on copy 1 of the VIDS/MAF, left of the accumulated work hours section. A sight inventory will be conducted by the technician prior to commencement of each task, and all shortages will be noted. Every measure must be taken to ensure that missing tools do not become a cause of FOD. Inventories will also be performed before a shift change, when work stoppage occurs, after maintenance has been completed, and before conducting an operational systems check on the equipment.2. When all tools are accounted for and all maintenance actions have been completed, the work center supervisor signs the VIDS/MAF, signifying that maintenance has been completed and that all tools have been accounted for. 3. If any tool is found to be missing during the required inventories, conduct an immediate search prior to reporting the work completed or signing off the VIDS/MAF. If the tool cannot be located, notify the maintenance officer or assistant maintenance officer via the work center supervisor and maintenance control to ensure that the aircraft or equipment is not released. If the tool cannot be located after the maintenance officers directed search, the person doing the investigation will personally sign a statement in the Corrective Action block of the VIDS/MAF that a lost tool investigation was conducted and that the tool could not be found. Subsequently, the normal VIDS/MAF completion process will be followed. The flight engineer/crew chief (senior maintenance man in the absence of an assigned crew chief) will assume the responsibilities of the work center supervisor applicable to the TCP in the event of in-flight maintenance or maintenance performed on the aircraft at other than home station. OCCUPATIONAL AWARENESS Learning Objective: Identify sources of information regarding hazards within the AM rating and recognize terms applicable to hazardous situations and materials.Many different materials are used in the workplace. Some are hazardous. You must know where to retrieve information on these materials used in and around naval aircraft. The MIMs give information on correct maintenance practices, but may not always give complete information regarding necessary safety practices.The Navy Occupational Safety and Health (NAVOSH) program was established to inform workers about hazards and the measures necessary to control them. The Department of Defense has established the Hazardous Material Information System (HMIS), which is designed to acquire, store, and disseminate data on hazardous material procured for use. The primary source for you to get the necessary information before beginning any operation involving the use of hazardous material is the Material Safety Data Sheet (MSDS). The MSDS, known as Form OSHA-20, is shown in figure 3-2. This nine-section form informs you of hazards involved, symptoms of exposure, protective measures required, and procedures to be followed in case of spills, fire, overexposure, or other emergency situations. The maintenance of safe and healthful working con-ditions is a chain-of-command responsibility. Imple-mentation begins with the individual sailor and extends to the commanding officer. The chain-of-command responsibilities are covered in OPNAVINST 5100.19B and OPNAVINST 5100.23B.Work center supervisors are responsible for training work center personnel in the use of the MSDS. Furthermore, they must ensure that personnel under their supervision have been trained on the hazards associated with the material and are equipped with the proper protective equipment prior to using any hazardous materials.All sections of the MSDS form are important, and contain information to accomplish a task without causing damage to equipment or personnel. Always ensure that you are using the correct MSDS with the material being used. You should check the MILSPEC, part number, federal stock number, and the name of themanufacturer. Never use the MSDS with different manufacturers. The formula for a given product may differ and still meet the specifications requirements. The handling and safety requirements will effectively change based on different manufacturers.Threshold Limit Value (TLV) in sections II and V of the MSDS are established by the American Conference of Governmental Industrial Hygienists (CGIH). TLVS refer to airborne concentrations of a substance and represent conditions that nearly all workers may be exposed, day after day, without adverse effects. You should know the effects of overexposure and the emergency procedures required prior to using any material.We have been taught about incompatibility, such as the mixing of oil and oxygen. Section VI (Reactivity Data) of the MSDS contains a list of materials and conditions to avoid that could cause special hazards. Prompt cleanup of spills and leaks will lessen the chance of personnel and the environment being harmed. Section VII (Spill or Leak Procedures) of the MSDS lists the required steps to be taken for cleanup and proper disposal methods.You should familiarize yourself and comply with section VIII (Special Protective Information) of the MSDS. In doing so, you will protect yourself and others from dangerous exposure. Some protective equipments are complex and require special training in proper use and care. Never use a respirator that you have not been tit-tested to wear. Always check to see that the cartridge installed meets the requirements of the MSDS. If you use a respirator you have not been trained for or fitted to, or with the wrong cartridge installed, it can be as dangerous to your health as wearing no protection at all. Figure 3-2.-Material safety data sheet.     Figure 3-2.-Material safety data sheetContinued.   Figure 3-3.-Line characteristics. You need to be aware of word usage and intended meaning as pertains to hazardous equipment and/or conditions. These terms are used in most technical manuals prepared for the Navy.The following is a list of safety hazard words and definitions as they appear in most naval aviation technical manuals.WARNING An operating procedure, practice, or condition, etc., that may result in injury or death if not carefully observed or followed.CAUTION An operating procedure, practice, or condition, etc., that may result in damage or destruction to equipment if not carefully observed or followed.NOTE An operating procedure, practice, or condition, etc., that is essential to emphasize.SHALL has been used only when application of a procedure is mandatory.SHOULD has been used only when application of a procedure is recommended.MAY and NEED NOT have been used only when application of a procedure is optional. WILL has been used only to indicate futurity, never to indicate any degree of requirement for application of a procedure. |

|

|

|