|

LAUNDRY PRESSING AND FINISHING

The press deck area of the laundry processes all clothing received from washing or tumbling operations that cannot be processed through the flatwork ironer. Uniform items made of synthetic or synthetic blends may be successfully finished by tumble

drying if the procedures outlined in the washing and drying sections are followed. Other cotton uniform coats, shirts, and trousers must be

pressed before they are worn. Laundry personnel working on the press deck must know how to operate a press and press clothing correctly. This requires practice and repetition of standard press lays for shirts and trousers. It also requires knowing the basics of the laundry press operation and following all safety precautions. LAUNDRY PRESSES

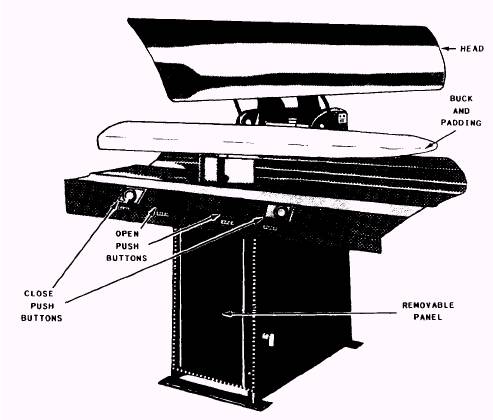

A laundry press is shown in figure 5-32.

A laundry press consists of a stationary padded buck fastened to a rigid metal frame. The head of the press is made of polished metal and is lowered

by a system operated by compressed air. Live steam is admitted to the head to heat it, and the condensed steam is carried away by a drain-pipe. A steam trap prevents live steam from entering the drainage system. A table for holding a garment undergoing pressing is

secured to the frame of the press beneath the buck. The buck of a press is your worktable. The size and shape of the buck may vary according to the function for which it was designed. The buck is padded in a specific way for satisfactory pressing. This padding must be in good condition at all times and must be changed when scorched, uneven, or worn. The amount and condition of padding affect head pressure, and you must readjust this pressure to get the amount required for good pressing. TYPES OF LAUNDRY PRESSES

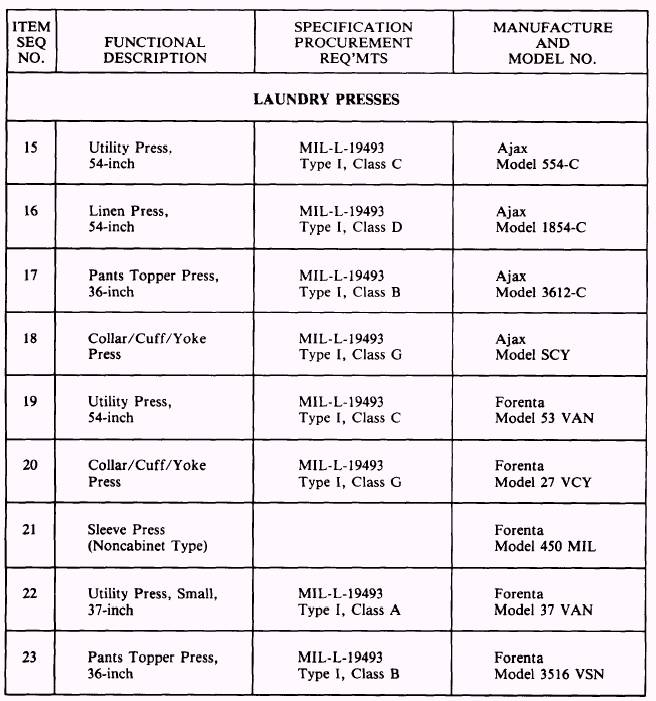

Figure 5-33 shows the many presses used afloat. There are several models used afloat; however, the operation of them is basically the same. The following are the basic types of presses installed aboard ship: 1. Tapered head- for general pressing of wearing apparel

2. Rectangular head- for general pressing of wearing apparel and flatwork items

3. Triple head- for pressing shirt collars and cuffs simultaneously

4. Sleeve press- for pressing sleeves of shirts In addition to presses you have your spray guns attached to press units. A spray gun is essential for dampening garments that are too dry for good pressing. Cold water is used to dampen the garments. A small amount of water sprayed on the last part of a garment being pressed is necessary to compensate for the moisture lost

while the other parts of the garment were pressed on the hot press.

Figure 5-32.- Utility laundry press basic parts.

Figure 5-33.- Laundry press listed for use aboard ship.

PRESS LAYOUTS layout of equipment. The layout of all laundry equipment in Navy ships is done by the Naval Sea When two or more presses are placed together Systems Command, and changes should not be so that garments may be alternately pressed on made without prior approval. each machine by one operator, the group of Figure 5-34 illustrates a single operator station presses is called a unit. consisting of two utility presses and one pants The placement of presses within a unit, or the topper press. On a large ship there maybe several placement of units in the laundry, is called the of these stations as shown in figure 5-35.

Figure 5-34.-Laundry press single operator station.

Figure 5-35.-Several single operator stations.

|