|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-630-12

plug cylinder, valve or filter ports to prevent entrance of

i.

A hydraulic pump (fig. 48), directly driven by the

foreign matter.

c.

engine crankshaft, supplies hydraulic oil under pressure to the

Installation. Before installing fittings, check to

control valve (fig. 4-8). As the lift and tilt levers are moved, oil

see if packing is required.

flows to the lift cylinders to raise the mast or to the tilt

(1) Remove plugs from ports and install fittings in

cylinders (fig. 4-8) to tilt the mast.

cylinders, valves or filter.

j.

Oil for the system is stored in the hydraulic

(2) Remove plugs from ends of hoses and connect

reservoir (fig. 4-8). As the oil returns to the reservoir, it flows

hoses to fittings.

through the hydraulic oil filter (fig. 4-8). A filter element

(3) Operate truck and lift and tilt mast and steer

indicator (fig. 4-8) is connected across the inlet and outlet of

truck to actuate hydraulic system.

the filter.

If the filter element becomes clogged and

(4) Stop truck engine and check level of oil in

contaminated, the indicator will show filter element condition.

hydraulic reservoir. Add oil as necessary to fill reservoir to

k.

Tilt cylinders are connected to the outer mast

proper operating level Refer to current lubrication order for

and to the frame below the toe plate. Hydraulic pressure

proper grade of oil

applied on either side of the cylinder rod will extend or retract

(5) Bleed hydraulic system as follows.

the rod. As the rod extends, it tilts the mast forward. As the

(a) Raise mast until forks are approximately three

rod is retracted, the mast tilts backward.

feet off the ground.

4-34. Hydraulic Lines and Fittings

(b) Open bleed screws located at the top of the

a.

Inspection. Inspect hydraulic hoses and tubes

cylinder until hydraulic oil comes out.

frequently. Check for leakage, damage, chafing and wear.

(c) Observe oil and check for air bubbles. When

Check all fittings for leakage and damage.

Replace

stream of oil is free of air bubbles, close bleed screws.

unserviceable components.

(d) Check level of hydraulic oil in reservoir. Fill

b.

Removal Before attempting to remove any

reservoir if necessary.

hydraulic lines or fittings, refer to paragraph 440 and drain

(e) Raise and lower mast and check for leaks and

reservoir if necessary. Remove toe and floor plates and front

proper operation. Tighten connections if necessary.

cowls or open side panels to gain access to hydraulic lines.

(1) Disconnect hoses or tubes at valve, cylinders,

4-35. Lift Chains

a.

filter or reservoir by removing hose clamps or disconnecting

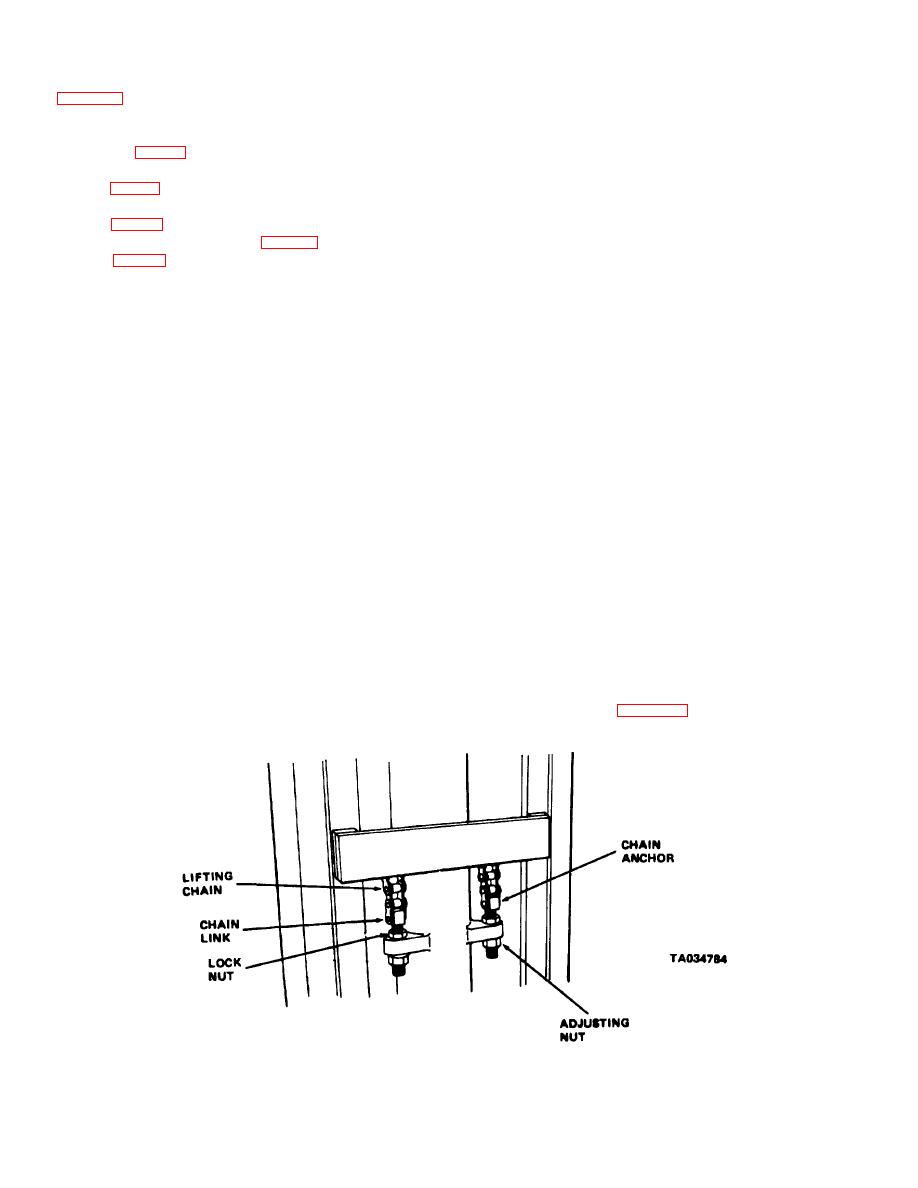

General. Extension of the two outer cylinders of

at fittings.

the cylinder cluster raises the chain bearing and crosshead.

(2) If necessary, remove any clamps mounting the

As the bearing raises the chains which are anchored at the

hose or tube to the truck.

rear of the cylinder cluster, the action raises the carriage.

b.

(3) If preformed packings are present when a fitting

Inspection. Inspect chains for wear, cracks and

is removed, mark fitting to insure installing packing when

other damage.

installing new fitting.

(1) Lower carriage and forks to the floor.

(4) Immediately plug ends of hose or tube and

(2) Refer to figure 4-9 and remove other pins and

chain links from chain anchors attached to cluster cylinder.

Figure 4-9. Lift chain and anchors, installed view.

TA034784

4-20

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |