|

111 W 151 Sewing Machine

The 111 W 151 sewing machine is also a singleneedle, lockstitch, rotary hook machine, intended for high-speed straight stitching of medium heavy materials. The 111 W 151 sewing machine differs from other models of the class 111 machines in that it has a single presser foot instead of the alternating presser foot. 111 W 152 Sewing Machine The 111 W 152 sewing machine is a singleneedle, lockstitch, compound feed machine with a vertical axis sewing hook. This machine has alternating pressers with a 3/8-inch lift. It has a safety clutch that prevents the hook from being damaged or getting out of time due to accidental strain. 111 W 153 Sewing Machine The 111 W 153 sewing machine is similar to the 111 W 152, but it is used for sewing heavy work such as automobile and truck upholstery, tents, awnings, and leather flight jackets. 111 W 154 Sewing Machine The 111 W 154 sewing machine is also similar to the 111 W 152, but its alternating pressers have a lift of 1/2 inch, and the machine is designed for stitching upholstery work, leather coats, and binding heavy materials such as felt padding. 111 W 155 Sewing Machine The 111 W 155 sewing machine is similar to the 111 W 154 except that its minimum stitches per inch is 3 1/2, and it has an adjustable lifting eccentric for instantly setting the alternating pressers to the minimum amount of lift required for the work to be sewn. FUNCTIONAL FEATURES The oiling parts for class 111 sewing machine are shown in figure 9-24A. Figure 9-24B identifies

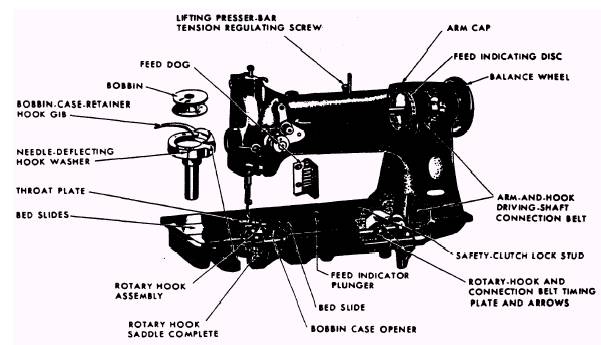

Figure 9-24B.-Class 111 sewing machine, front view showing components and parts. 9-19 the component parts. The primary feature of each component is explained in the following text: Lifting Presser Bar Tension Regulating Screw. Regulates the pressure on the alternating presser foot. Feed Indicating Disc. Indicates the number of stitches per inch which are being made by the machine. Balance Wheel. Provides a connection between the driving unit and the sewing machine head. Arm-and-Hook Driving Shaft Connection Belt. Connects the upper arm shaft with the hook driving shaft. Feed Dog. Feeds the material from the under side. Rotary Hook Assembly. Contains the mechanism that forms the lockstitch by using the needle and bobbin threads. Bobbin. Contains the lower thread used in forming the lockstitch. Bobbin Case Retainer Hook Gib. Holds the bobbin case in the bobbin race. Needle-deflecting Hook Washer. Deflects the needle so the rotary hook will not strike the needle. Throat Plate. Surrounds the feed dog and keeps the material from slipping after the feed dog has been adjusted to the proper height. Bed Slides. Covers the feed eccentric and rotary hook assembly on each side of the throat plate. Feed Indicator Plunger. Used in connection with the feed indicator to regulate the number of stitches per inch desired. Safety-clutch Lock Stud. Re-engages the needle with the hook driving assembly after clearing a thread jam. Bobbin Case Opener. Prevents thread from jamming underneath the throat plate on the bobbin case base. 239.449

Figure 9-25A.-Class 111 sewing machine, side view. Rotary Hook Saddle Complete. The rotary hook is operated by the spiral driving pinion gear, which, in turn, is operated by the hook driving gear located on the hook driving shaft. Rotary Hook and Connection Belt Timing Plate and Arrows. Used to time the arm shaft with the hook driving shaft. The following parts are shown in the side view of the Class 111 sewing machine (figures 9-25A and 9-25 B). Thread Take-up Lever. Pulls the needle thread against the tension disc after the lockstitch is formed at the rotary hook and pulls sufficient thread from the spool to make the next stitch. Vibrating Presser Bar Tension Regulating Screw. Regulates the pressure on the presser foot. Only sufficient pressure to hold the material securely is needed. Face Plate. Covers and protects the mechanism of the two pressel feet and needle bar. 239.282

Figure 9-25B.-Class 111 sewing machine, side view showing oiling points. Needle Thread Lubricator. Lubrication of the thread when sewing leather. Lubrication of the thread prevents it from fraying, and prevents the needle from becoming hot when sewing at high speed. Needle Thread Tension. Regulates the tension on the needle thread so that the lockstitch may be adjusted properly. Needle Thread Controller Spring Assembly. Removes sufficient slack from the needle thread when the needle is descending to prevent the needle from splitting the thread. Needle Bar. Holds the needle and carries the thread to the rotary hook where the lockstitch is formed. Vibrating Presser Foot. Holds the material in place while the alternating presser foot rises to

make another stitch. Lifting Presser Foot. Holds the material in place while the vibrating presser foot and feed dog go forward to get material for the next stitch. The class 111 machine is a compound feed machine. This means that the feed dog, vibrating

presser foot, and needle move together to feed the material. Some class 111 machines are equipped with a compound feed only, such as the 111 W 151; and others are equipped with a combination of the compound feed and alternating presser foot that holds the material while the needle and vibrating presser foot are moving into position for the next stitch, such as the 111 W 155. Perhaps the description of the feed mechanism gave you a hint that the class 111 sewing machine is a more complicated machine than the class 31. It is indeed.

|