|

Wire Rope End Connections Wire rope end connections must be as specified by the manufacture. The most common type of end connection used in the NCF is the wedge socket (fig. 12-40). Wedge sockets develop only 70 percent of the breaking strength of the wire rope due to the crushing

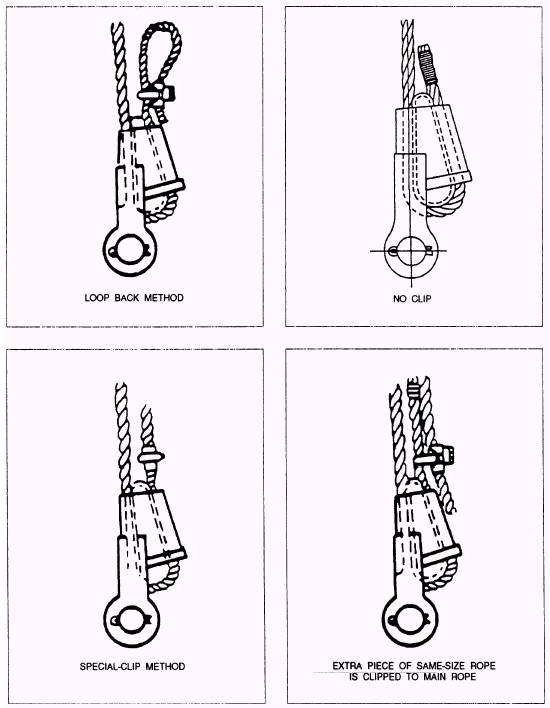

action of the wedge. Swage socket, cappel socket, and zinc (spelter) socket wire rope end connections all provide 100 percent of the breaking strength of the wire rope when properly made. Exercise caution when wedge socket connections are used to make rated capacity lifts. Wedge sockets are particularly subject to wear, faulty component fit, and damage from frequent change outs, and are highly vulnerable to inadvertent wedge release and disassembly in a two-blocking situation. NOTE: Two-blocking is hoisting the hook block sheaves against the boom tip sheaves. Wedge sockets must be installed as specified in the following procedures: 1. Cut and remove any section of wire rope used in a socket that was subject to sharp bending and crushing before resocketing. 2. Install the wedge socket carefully, so the wire rope carrying the load is in direct alignment with the eye of the socket clevis pin. This ensures the load pull is direct. 3. Place the socket upright and bring the rope around in a large, easy-to-handle loop. Extend the dead end of the wire rope from the socket for a distance of at least one rope lay length. Insert the wedge in the socket, permitting the rope to adjust around the wedge. 4. As a safety precaution, install a wire rope clip on the dead end of the wire rope that comes out of the wedge socket (fig. 12-41). Measure the distance from the base of the wedge socket to the clamp. This measurement is used as a guide to check if the wire rope is slipping in the wedge socket. NOTE: Do not attach the wire rope clip to the dead end and live end of the wire rope that comes out of the

Figure 12-41.-Wedge socket clip method.

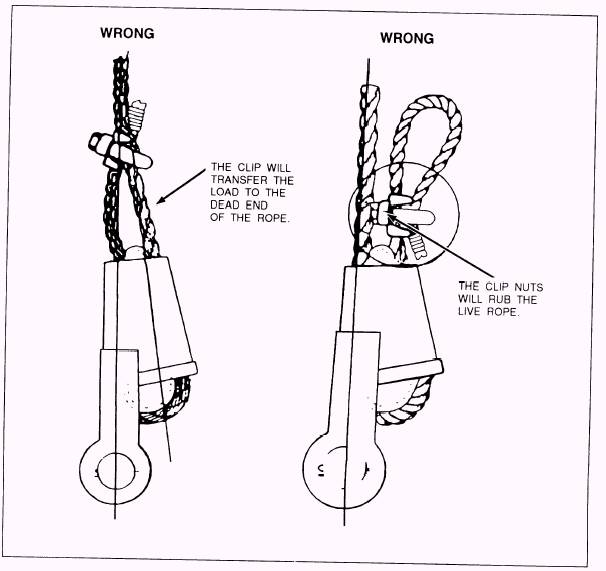

Figure 12-42.-Improper wire rope clip placement. wedge socket. Improper wire rope clip placement is shown in figure 12-42. 5. Secure the socket to a support and carefully take a strain on the live side of the rope to ensure the proper initial seating of the wedge. Increase the load gradually

until the wedge is fully seated. Avoid sudden shock loads.

|