|

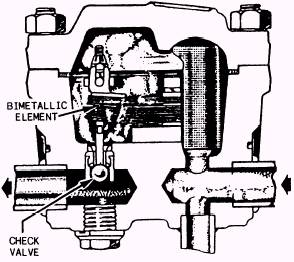

Bimetallic

Steam Traps Bimetallic

steam traps are used in many ships to drain condensate from main steam lines,

auxiliary steam lines, and other steam components. The main working parts of

this type of steam trap are a segmented bimetal-lic element and a ball-type

check valve (fig. 13-36).

The

bimetallic element consists of several bimetallic strips fastened together in a

segmented fashion. One end of the bimetallic element is fastened rigidly to a

part of the valve body. The other end, which is free to move, is fastened to

the top of the stem of the ball-type check valve.

Line

pressure acting on the check valve tends to keep the valve open. When steam

enters the trap body, the bimetallic element expands unequally because of the

different response to the temperature of the two met-als. The bimetallic

element deflects upward at its free end. This moves the valve stem upward and

closes the valve. As the steam cools and condenses, the bimetallic element

moves downward toward the horizontal posi-tion. This opens the valve and allows

some condensate to flow out through the valve. As the flow of condensate begins,

an un-balance of line pressure across the valve is created. Since the line

pressure is greater on the upper side of the ball of the check valve, the valve

now opens wide and allows a full capacity flow of condensate.

Figure 13-36.-Bimetallic

steam trap.

|