|

|||

|

|

|||

|

Page Title:

TRUCK, FORKLIFT, DED PNEUMATIC TIRE, 10,000 LB. CAPACITY ROUGH TERRAIN, ARTICULATED FRAME STEER (DRESSER INDUSTRIES MODEL M10... |

|

||

| ||||||||||

|

|

LUBRICATION ORDER

*LO 10-3930-643-12

13 DECEMBER 1990

TRUCK, FORKLIFT, DED

PNEUMATIC TIRE, 10,000 LB. CAPACITY

ROUGH TERRAIN, ARTICULATED FRAME STEER

(DRESSER INDUSTRIES MODEL M10A, MHE 236)

(NSN 3930-01-054-3833)

Reference TM 10-3930-643-10, TM 10-3930-643-20 and TM 9-2300-422-23&P

TB

Engine oil/transmission fluids must be sampled at the appropriate intervals as prescribed in 43-0210.

Intervals (on-condition or hard time) and the related man-hour times are based on normal operation. The man-hour time

specified is the time you need to do all the services prescribed for a particular interval. On-condition (OC) oil sample inter-

vals shall be applied unless changed by the Army Oil Analysis Program (AOAP) laboratory. Change the hard time interval

if your lubricants are contaminated or if you are operating the equipment under adverse operating conditions including

longer-than usual operating hours. The hard time interval maybe extended during periods of low activity. If extended,

adequate preservation precautions must be taken. Hard time intervals will be applied in the event AOAP laboratory sup-

port is not available.

Oil filters shall be serviced/cleaned/changed as applicable, when they are known to be contaminated, or clogged; service

is recommended by AOAP laboratory analysis, or at prescribed hardtime intervals.

This LO is for crew(C)) or unit (O) maintenance. Lube intervals (on-condition or hard time) are based on normal operation.

Lube more during constant use, and less during inactive periods. Use correct grade of lubricant for seasonal temperature

expected.

On the pictures a dash line (-) means lube points on both sides.

Clean parts with dry cleaning solvent (SD), type II, or equivalent. Use cleaning compound solvent (RBC) on powder-

fouled parts. Dry before lubricating. DO NOT use fluid or semi-fluid lubricant on SFD lubricated surface. Wipe surface dry.

Before you start your lube service.

NEVER

ALWAYS

a. Clean grease fittings before lubrication.

a. Use wrong type/grade grease.

b. Use the lubrication order as your guide.

b. Use too much lubricant.

Reporting Errors and Recommending Improvements. You can help improve this manual. If you find any mistakes or if you

know of a way to improve the procedures, please let us know. Mail your letter or DA Form 2028 (Recommended Changes

to Publications and Blank Forms) direct to: Commander, ATTN: AMSTA-MB, Warren, Ml 48397-5000. A reply will be

furnished to you.

Approved for public release: distribution is unlimited.

* This LO supersedes the lubrication instructions contained in LO 10-3930-843-12 dated 12 March 1990.

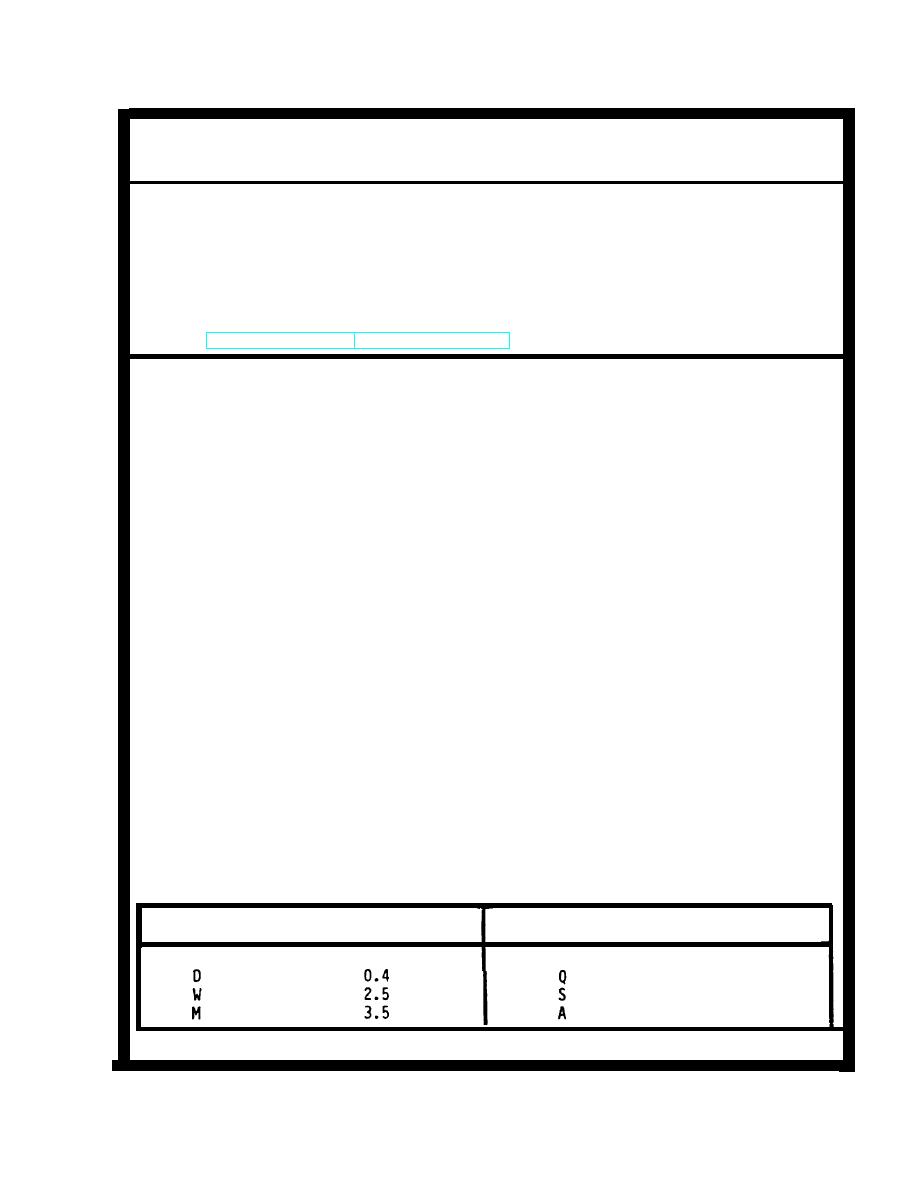

TOTAL MAN-HOURS

TOTAL MAN-HOURS

MAN-HOURS

MAN-HOURS

INTERVAL

INTERVAL

4.0

4.5

5.0

Card 1 of 17

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |