|

SCAFFOLDING As the working level of a structure rises above the reach of crew members on the ground, temporary elevated platforms, called SCAFFOLDING, are erected to support the crew members, their tools, and materials. There are two types of scaffolding in use today: wood and prefabricated. The wood types include the swinging scaffold, which is supported on the ground. For information concerning the wood type of scaffolding, refer to Builder 3 & 2, volume 1, NAVEDTRA 12520, chapter 4. The prefabricated type

is made of metal and is put together in sections as needed. As a CE, you will be working more with the prefabricated type of scaffolding.

This section provides only general information on prefabricated scaffolding. For further details of scaffolding, consult the latest copy of the Code of

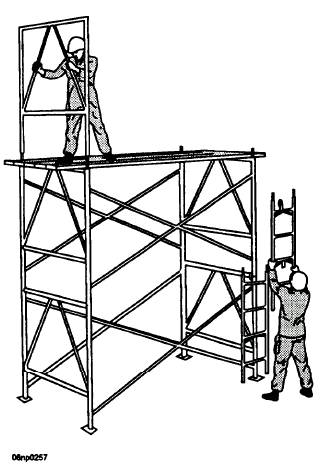

Federal Regulations (29 CFR 1926). PREFABRICATED SCAFFOLDING Several types of patent-independent scaffolding are available for simple and rapid erection, as shown in

figure 5-78. The scaffold uprights are braced with

Figure 5-78.- Assembling prefabricated independent-pole scaffolding. diagonal members, as shown

in figure 5-79, and the working level is covered with a platform of planks. All bracing must form triangles, and the base of each column requires adequate footing plates for bearing area on the ground. The patented steel scaffolding is usually erected by placing the two uprights on the ground and inserting the diagonal members. The diagonal members have end fittings that permit rapid locking in position. The first tier is set on steel bases on the ground. The second tier has the bottom of each upright locked to the top of the lower tier. A third and fourth upright can be placed on the ground level and locked to the first set with diagonal bracing. The scaffolding can be built as high as desired, but high scaffolding should be tied to the main structure. Steel and aluminum scaffolding is used to speed up construction and maintenance operations. Many types

are available for interior work and erection. This kind of scaffolding is used around many construction sites because it can be disassembled and transported whenever necessary. The scaffolds are mounted on steel casters with brakes and adjustable supports, which permit quick movement and positioning of each tower This scaffolding is equipped with special trussed

planks, 12 feet long, that are placed to enable crew members to be within comfortable and safe working distance of all working space. Prefabricated scaffolding of this type comes in three categories: light, medium, and heavy duty. Light-duty

scaffolding has nominal 2-inch-outside-diameter steel-tubing bearers. Posts are spaced no more than 6 to 10 feet apart. The load it can handle is 25 pounds per square foot. Medium-duty scaffolding normally uses 2- inch-outside-diameter steel-tubing bearers. Posts should be spaced no more than 5 to 8 feet apart. If 2 1/ 2-inch-outside-diameter steel-tubing bearers are used,

posts are spaced 6 to 8 feet apart. The load it can handle is 50 pounds per square foot. Heavy-duty scaffolding should have bearers of 2 1/ 2-inch-outside-diameter steel tubing with the posts spaced not more than 6 feet 6 inches apart. The load it can handle is 75 pounds per

square foot. To find the load per square foot of a pile of materials on a platform, divide the total weight of the pile by the

number of square feet of platform it covers. SAFETY The following safety precautions must be observed by all persons working on scaffolds or tending other persons who are working on scaffolds. Construction

Figure 5-79.- Prefabricated independent-pole scaffolding. Electrician petty officers must not only observe the safety precautions themselves, but they must also issue them to their crew and ensure that the crew observes them. Scaffolds must be kept clear of accumulations of tools, equipment, materials, and rubbish. No scaffold may be used for the storage of materials in excess of those currently required for the job. Tools not in immediate use on scaffolds must be stored in containers to prevent tools left adrift from being knocked off. Tool containers must be lashed or otherwise secured to the scaffolds. Throwing objects to or dropping them from scaffolds is absolutely prohibited. Hand lines must be used for raising or lowering objects that cannot be passed hand to hand A standard guardrail and toeboard should be provided on the open side of all platforms 5 feet or more above ground; otherwise, safety belts tied off to safety lines must be used. while in use. Personnel must not be allowed to use damaged or weakened scaffolds. Access to scaffolds must be by standard stairs or by fixed ladders only. No person should remain on a rolling scaffold while it is being moved. All scaffolds must be maintained in safe condition, and they must not be altered or disturbed

When scaffolding is being dismantled, it should be cleaned and made ready for storage or use. Scaffolding that is not ready for use should never be stored.

|